Browse by Category View all categories

- Activities / Events

- Animals & Pets

- Antiques / Collectibles

- Automobiles

- Automotive Parts - Accessories

- Aviation / Planes

- Beauty & Well being

- Boats / Watercraft

- Business Directory

- Business to Business

- Charity Events - Listings

- Clothing / Access...

- Computers / Networking

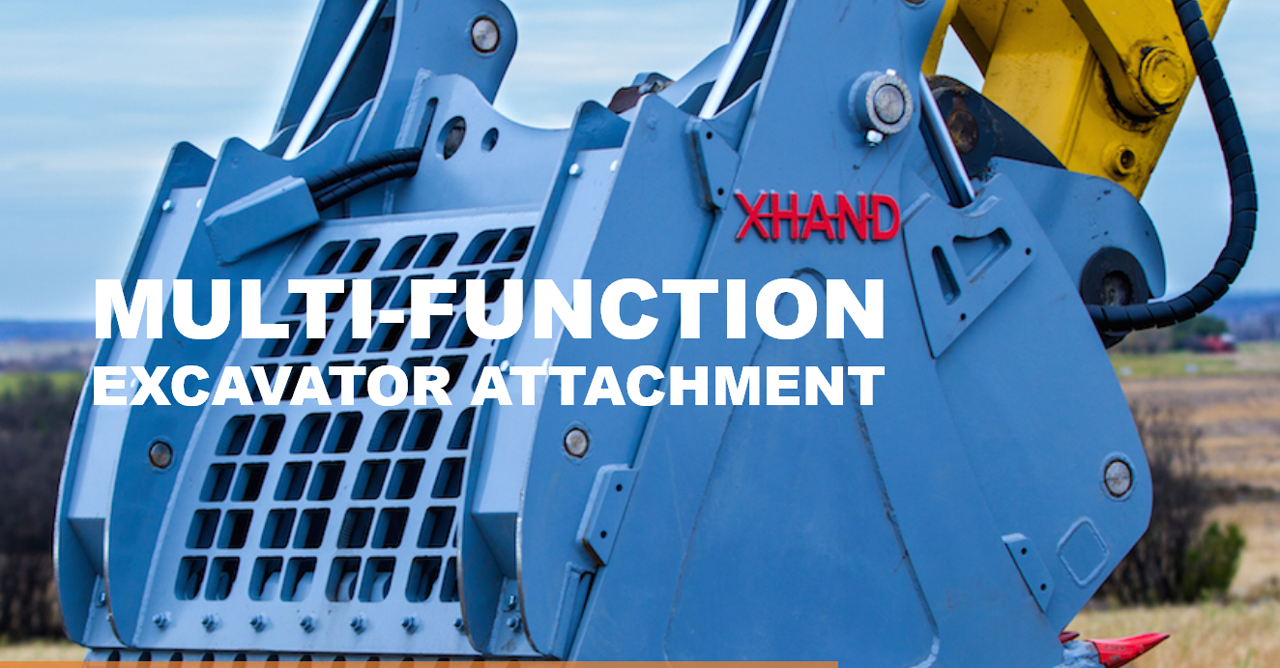

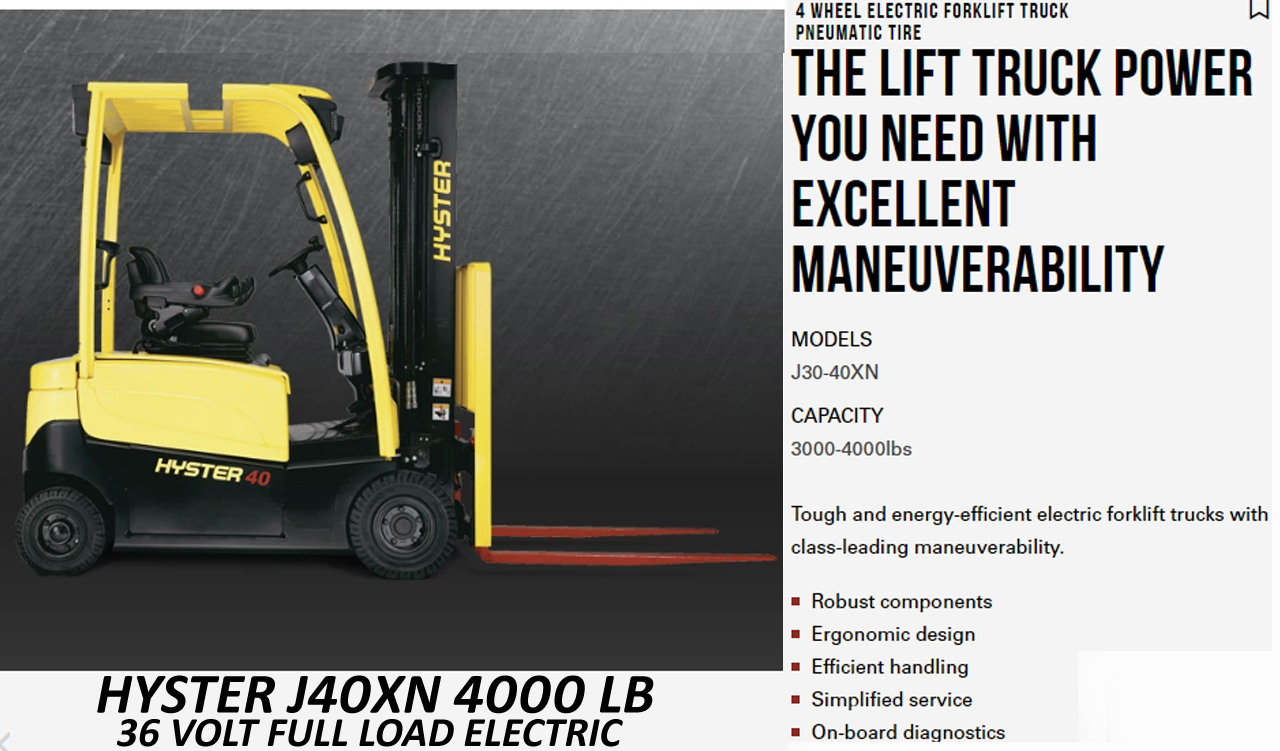

- Construction / Logging

- Daily - Deals & Services

- Dine / Food / Beverage

- Education / Training

- Electronics - Audio - Video

- Electronics Accessories

- Employment - Careers

- Farming / Agriculture

- Fashion - Style

- Furniture & Appliances

- Heavy Trucks - Trailers

- Home - Garden - Building

- Industrial - Machinery

- Jewelry / Watches

- Jobs - Services Short Term

- Laptops & Tablets

- Learning - Courses - Music

- Leasing - Loans - Mortgages

- Local Annoucements - Events

- Motorsports / Racing

- Office/Restaurant

- Personal Services

- Photography / Video

- Public News / Events

- RVs / Trailers / Access..

- Real Estate / Rentals

- Resorts/Travel/Vacations

- Services Home - Garden

- Sporting Goods

- Tools Hand / Power

- Wanted/Barter/Free

Australia

Australia Bermuda

Bermuda Brazil

Brazil Canada

Canada France

France Italy

Italy Mexico

Mexico United Kingdom

United Kingdom United States

United States